moulds texturing Companies: Elevating Product Aesthetics and Functionality

moulds texturing businesses concentrate on growing unique and intricate surface textures on molds utilized in various manufacturing strategies, such as injection molding, blow molding, and rotational molding. These textures can considerably enhance the advent and performance of the very last products.

moulds texturing Companies: An Overview

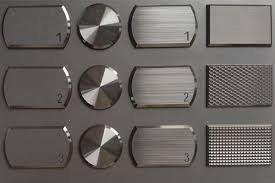

| Feature | Description |

| Function | Create unique surface textures on molds used in manufacturing processes. |

| Methods | Mechanical engraving, chemical etching, laser texturing. |

| Benefits | Enhanced aesthetics, improved functionality (slip resistance, anti-reflection, heat dissipation, increased surface area). |

| Applications | Automotive, consumer goods, medical devices, packaging. |

| Selection Criteria | Expertise, technology, quality control, communication. |

| Impact | Contributes to the creation of innovative and high-quality products. |

How Mould Texturing Works:

Mold texturing entails growing patterns or textures on the mould floor. This may be performed via numerous techniques, which includes:

- Mechanical Engraving: Using specialised tools to carve or engrave the preferred texture into the mould floor.

- Chemical Etching: Applying chemical compounds to selectively etch away quantities of the mold surface, developing a textured pattern.

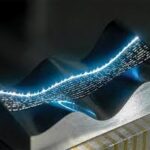

- Laser Texturing: Using high-powered lasers to ablate or soften the mold floor, producing specific and tricky textures.

Benefits of Mold Texturing:

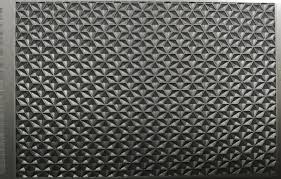

- Enhanced Aesthetics: Textured surfaces can add visual enchantment and depth to merchandise, making them greater appealing to clients.

- Improved Functionality: Textures can enhance product performance in numerous methods:

- Slip Resistance: Creating textured surfaces on non-slip objects like automobile mats, shower flooring, and grips.

- Anti-Reflective Properties: Reducing glare and enhancing visibility on surfaces like lenses and displays.

- Improved Heat Dissipation: Enhancing warmth switch in packages like electronics cooling.

- Increased Surface Area: Creating textures on products like filters or warmth exchangers to enhance their efficiency.

Applications of Mold Texturing:

Mold texturing is used in a wide variety of industries, together with: