Laser Texturing Machines: Precision Engineering for Enhanced Surfaces

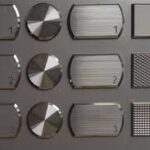

Laser texturing machines are sophisticated tools that utilize high-energy laser beams to create intricate patterns and textures on various materials.1 This advanced technology offers unparalleled precision and control, enabling manufacturers to enhance the properties and performance of their products in ways previously unimaginable.2

Laser Texturing Machines: An Overview

| Feature | Description |

| Function | Use high-energy laser beams to create intricate patterns and textures on materials. |

| Methods | Ablation, melting and reflow, inducing phase changes. |

| Key Components | Laser source, beam delivery system, motion control system, process control system. |

| Applications | Manufacturing, electronics, biomedical, and more. |

| Benefits | Precision and control, versatility, non-contact, high throughput. |

| Future Trends | Multi-material processing, in-situ control, new applications. |

| Impact | Revolutionizing surface engineering and manufacturing by enabling the creation of advanced materials. |

How is Work:

These machines work by directing a focused laser beam onto the material’s surface.3 The laser’s energy can be used to:

- Ablate: Remove material in a precise and controlled manner, creating microscopic features like pits, grooves, or channels.4

- Melt and Reflow: Melt the surface layer, causing it to flow and form textures.5

- Induce Phase Changes: Alter the material’s microstructure, creating regions with different properties.6

Key Components of a Laser Texturing Machine:

- Laser Source: Generates the high-energy laser beam, typically using technologies like CO2 lasers, Nd:YAG lasers, or fiber lasers.

- Beam Delivery System: Guides and focuses the laser beam onto the material’s surface using mirrors and lenses.7

- Motion Control System: Precisely positions and moves the material or the laser head to create the desired patterns.

- Process Control System: Monitors and controls various parameters like laser power, pulse duration, and beam focus.

Applications of Laser Texturing Machines:

The versatility of laser texturing machines has led to their widespread adoption across various industries:

- Manufacturing: Creating non-stick surfaces on cookware, enhancing wear resistance of mechanical components, improving adhesion of coatings.8

- Electronics: Creating microfluidic channels for lab-on-a-chip devices, improving solar cell efficiency, enhancing heat dissipation of electronic components.9

- Biomedical: Creating biocompatible surfaces for implants, designing surfaces for tissue engineering, improving the sensitivity of biosensors.10

Advantages of Using Laser Texturing Machines:

- Precision and Control: Laser texturing machines offer exceptional precision and control over the created textures, allowing for complex and intricate designs.11

- Versatility: Applicable to a wide range of materials, including metals, plastics, ceramics, and even biological tissues.12

- Non-Contact Process: Reduces the risk of damaging the material during processing.13

- High Throughput: Automation capabilities enable high-volume production.14

Future of Laser Texturing Machines:

Ongoing research and development are pushing the boundaries of laser texturing technology.15 Future advancements include:

- Multi-material processing: Combining laser texturing with other techniques like additive manufacturing and coating deposition.16

- In-situ process monitoring and control: Real-time feedback and adaptive control for improved precision and consistency.

- New applications: Exploring novel applications in areas like energy storage, photonics, and quantum technologies.

Conclusion:

Laser texturing machines are revolutionizing surface engineering and manufacturing by enabling the creation of complex and functional surfaces with unprecedented precision.17 As technology continues to advance, these machines will play an increasingly vital role in various industries, driving innovation and improving product performance.

If you would like, you can request a more focused article on a specific aspect of laser texturing machines, such as their applications in a particular industry or the different types of lasers used.