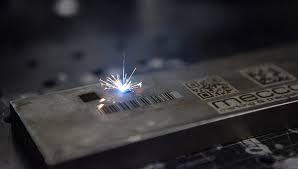

What is laser marking? is a process that uses a focused laser beam to alter the surface of a material to create marks, text, or patterns. Unlike engraving or etching, laser marking does not remove material but instead changes the material’s properties or appearance. This makes it an ideal solution for permanent and precise markings across various industries.

Laser marking is widely used for branding, product identification, and regulatory compliance due to its ability to produce high-quality, durable, and tamper-resistant marks.

How Does Work?

involves directing a laser beam onto the material’s surface. The energy from the laser causes a reaction in the material, such as discoloration, oxidation, or annealing. Depending on the material and the desired result, laser marking can create clear, sharp, and contrasting marks.

Types

There are four main types of laser marking, each with unique properties:

Annealing Marking

Commonly used for metals like stainless steel and titanium.

Creates marks through localized heating, causing a color change without material removal.

Often used for medical instruments, watches, and jewelry.

Engraving Marking

Removes material to create a shallow mark with depth.

Ideal for detailed logos, text, or patterns on metals and plastics.

Foaming Marking

Produces a raised mark on plastic materials by creating small bubbles within the material.

Common in consumer electronics and household items.

Color Change Marking

Changes the color of the material without removing or damaging its surface.

Suitable for soft materials like plastics.

Materials Suitable for Laser Marking

Laser marking can be used on a wide range of materials, including:

Metals: Stainless steel, aluminum, brass, titanium, and gold.

Plastics: ABS, polycarbonate, acrylic, and nylon.

Glass: Mirrors, windows, and bottles.

Ceramics: Tiles and mugs.

Coated Surfaces: Painted or anodized metals.

Applications

is a versatile process with applications in various industries:

- Industrial Manufacturing

is used to create serial numbers, barcodes, and product identification marks. These markings ensure traceability and compliance with industry standards. - Medical Equipment

Marking surgical instruments, implants, and medical devices helps ensure traceability and meets strict healthcare regulations. - Automotive Industry

Used to mark engine components, VIN numbers, and other critical parts for identification and quality assurance. - Electronics

Laser marking is ideal for labeling electronic components, circuit boards, and consumer gadgets. - Jewelry and Luxury Goods

adds intricate patterns, logos, and personalized engravings to jewelry and high-end products. - Packaging

Manufacturers use to print expiration dates, batch numbers, and barcodes on packaging.

Advantages of Laser Marking

Permanent Markings: Laser markings are durable, resistant to wear, and unaffected by harsh environments.

High Precision: It allows for intricate designs and small text with excellent clarity.

Eco-Friendly: The process is clean and generates minimal waste.

Non-Contact Process: Ensures no damage to the material being marked.

Versatility: Works on a wide range of materials and applications.

Cost-Effective: Once installed, laser marking systems require minimal maintenance.

Types of Laser Marking Machines

There are three primary types of laser marking machines:

Fiber Lasers:

Best for marking metals and industrial applications.

Common in the automotive and aerospace industries.

CO2 Lasers:

Ideal for marking non-metal materials like wood, glass, and plastics.

Often used in packaging and signage.

UV Lasers:

Perfect for delicate materials requiring high precision, such as glass and certain plastics.

Widely used in electronics and medical industries.

How to Choose a Laser Marking Machine

When selecting a laser marking machine, consider:

Material Type: Ensure the machine supports the material you plan to work with.

Marking Speed: Faster machines are suitable for large-scale production.

Power Output: Choose the right power level based on the material thickness and type.

Software: Ensure compatibility with design programs like AutoCAD or CorelDRAW.

Budget: Higher-powered machines with larger work areas typically cost more.

Conclusion

an innovative and efficient solution for creating permanent and precise markings on various materials. Its applications across industries like automotive, healthcare, and electronics demonstrate its versatility and importance. Whether for branding, regulatory compliance, or personalization, laser marking delivers durable and high-quality results that stand the test of time.