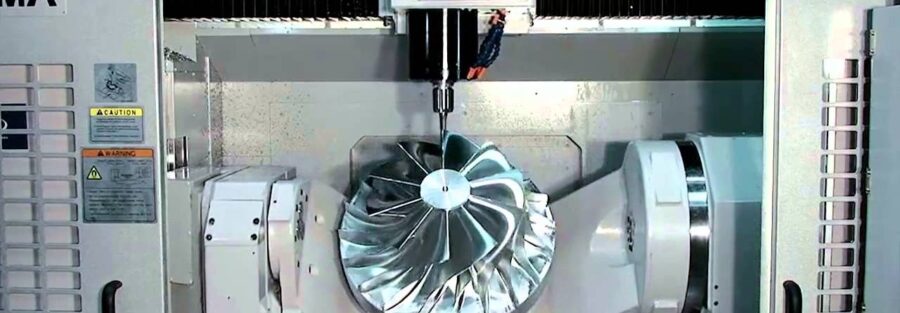

Five-Axis Machining stands as a pinnacle of modern manufacturing, enabling the creation of intricate and highly precise parts that were once deemed impossible or prohibitively expensive. It’s a significant leap beyond traditional three-axis machining, offering enhanced capabilities and opening doors to innovative designs.

| Feature | Description | Benefits | Applications |

| Axes of Movement | * Linear: X, Y, Z axes (traditional) <br> * Rotational: A, B (or A, C) axes (added) | Increased freedom of movement, enabling complex machining. | Aerospace components, medical implants, complex molds, intricate prototypes. |

| Complex Geometries | Ability to machine intricate shapes, undercuts, curved surfaces, and complex details. | Enables the production of parts with highly complex designs, previously difficult or impossible to create. | Turbine blades, orthopedic implants, complex engine components. |

| Reduced Setups | Machining multiple sides of a part in a single setup. | Improved accuracy, reduced potential for errors, shorter manufacturing times, and increased efficiency. | Complex parts requiring multiple machining operations. |

| Improved Surface Finish | Maintaining optimal cutting angles throughout the machining process. | Smoother surface finishes, reduced or eliminated need for secondary finishing operations. | Molds, dies, and high-precision components. |

| Shorter Cycle Times | Fewer setups and optimized cutting paths. | Increased productivity, reduced manufacturing costs. | High-volume production, rapid prototyping. |

| Enhanced Tool Life | Maintaining optimal cutting angles reduces stress on cutting tools. | Extended tool lifespan, reduced tooling costs. | Machining hard materials, prolonged machining operations. |

| Machine Configurations | * Table-Table <br> * Head-Table <br> * Head-Head | each configuration has it own pros and cons, relative to the job being machined. | Various Industries, for a variety of component types. |

| Industry Applications | * Aerospace <br> * Medical <br> * Automotive <br> * Mold and Die <br> * Energy | Allows for the production of highly specialized and advanced parts that keep these advanced industries moving forward. | Aircraft, medical devices, car engines, tooling, energy production equipment. |

Understanding the Basics:

Imagine a traditional three-axis CNC machine. It moves the cutting tool along three linear axes: X (left-right), Y (front-back), and Z (up-down). This allows for machining in three directions, which is suitable for many parts.

Now, picture adding two more axes of movement. In a five-axis machine, these additional axes are typically rotational. They are often referred to as “A” and “B” or “A” and “C” axes. These rotational movements allow the cutting tool or the workpiece to tilt and rotate during the machining process.

Why Five Axes Matter:

The added rotational capabilities of five-axis machining provide several crucial advantages:

- Complex Geometries: The ability to tilt and rotate the cutting tool or workpiece allows for the machining of highly complex shapes with undercuts, curved surfaces, and intricate details. This is especially vital in industries like aerospace, medical, and mold making.

- Reduced Setups: With three-axis machining, complex parts often require multiple setups, meaning the workpiece must be repositioned and reclamped several times. Each setup introduces potential errors and increases manufacturing time. Five-axis machining allows for machining multiple sides of a part in a single setup, improving accuracy and efficiency.

- Improved Surface Finish: By adjusting the tool’s orientation, five-axis machining can maintain optimal cutting angles, resulting in smoother surface finishes and reducing the need for secondary finishing operations.

- Shorter Cycle Times: Fewer setups and optimized cutting angles lead to shorter machining times, increasing productivity and reducing manufacturing costs.

- Enhanced Tool Life: By maintaining optimal cutting angles, five-axis machining reduces stress on the cutting tool, extending its lifespan and reducing tooling costs.

How it Works:

There are different configurations of five-axis machines, but they generally fall into two categories:

- Table-Table: In this configuration, both rotational axes are located on the machine’s table, which holds the workpiece.

- Head-Table: In this configuration, one rotational axis is on the machine’s head, which holds the cutting tool, and the other is on the table.

- Head-Head: Both rotational axis are located on the machines head.

Regardless of the configuration, the machine’s control system precisely coordinates the movement of all five axes to achieve the desired part geometry. This requires sophisticated software and highly skilled machinists.

Applications Across Industries:

Five-axis machining has revolutionized manufacturing in various sectors:

- Aerospace: Manufacturing complex turbine blades, structural components, and engine parts.

- Medical: Creating intricate surgical instruments, orthopedic implants, and prosthetics.

- Automotive: Producing complex engine components, molds for plastic parts, and styling prototypes.

- Mold and Die: Machining complex molds and dies for injection molding and die casting.

- Energy: Manufacturing components for turbines, pumps, and other energy-related equipment.

The Future of Five-Axis:

As technology advances, five-axis machining continues to evolve. Advancements in CNC controls, cutting tools, and software are further enhancing its capabilities and expanding its applications. The integration of automation and robotics is also driving the adoption of five-axis machining in high-volume production environments.

In conclusion, five-axis machining is a powerful manufacturing technology that enables the creation of complex and precise parts with increased efficiency and accuracy. Its ability to handle intricate geometries and reduce setups makes it an essential tool for industries requiring high-quality, high-performance components.