Chemical Etching Services In today’s world of intricate designs and demanding manufacturing requirements, chemical etching services stand out as a crucial tool for creating precise and complex parts. Far beyond simple material removal, this process offers a level of detail and accuracy that traditional machining methods often struggle to achieve.

What are Chemical Etching Services?

Chemical etching services involve the use of chemical solutions to selectively remove material from a substrate, typically metal. This process allows for the creation of incredibly detailed and intricate patterns, shapes, and features on a wide range of materials. It’s a subtractive manufacturing technique that offers unparalleled precision and repeatability.

| Category | Description/Details | Key Aspects | Applications | Choosing a Provider |

| What are Chemical Etching Services? | Selective material removal using chemical solutions, creating intricate patterns on substrates (typically metals). | * Precision and repeatability. <br> * Subtractive manufacturing. | Electronics, aerospace, automotive, medical devices, decorative/artistic, filters/grids. | Experience, quality control, technology, customer service, turnaround time. |

| Process Steps | 1. Design & Preparation (CAD) <br> 2. Substrate Preparation <br> 3. Resist Application <br> 4. Pattern Transfer <br> 5. Etching <br> 6. Resist Removal & Cleaning <br> 7. Finishing (optional) | * Digital design to photomask/screen. <br> * Protective resist application. <br> * Chemical removal of unprotected areas. <br> * Cleaning and optional finishing. | ||

| Why Choose Chemical Etching Services? | High precision, cost-effectiveness for complex designs, versatility (wide range of materials), stress-free manufacturing, rapid prototyping & production, design flexibility. | * Fine details and tight tolerances. <br> * Cost-effective for intricate parts. <br> * Applicable to various metals and some non-metals. <br> * No stress on material. <br> * Suitable for prototypes and mass production. | ||

| Applications (Specific Examples) | * Electronics: Lead frames, connectors. <br> * Aerospace: Lightweight components. <br> * Automotive: Engine parts. <br> * Medical: Implants, surgical tools. <br> * Decorative: Jewelry, signage. <br> * Filters: Precision grids. | |||

| Key Considerations When Choosing a Provider | Experience & expertise, quality control, equipment & technology, customer service & communication, turnaround time. | * Proven track record. <br> * Consistent and accurate results. <br> * State-of-the-art equipment. <br> * Clear communication. <br> * Meeting project deadlines. |

How Does it Work?

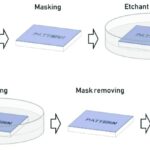

The process generally involves these key steps:

- Design and Preparation: The desired pattern or design is created digitally using CAD software. This design is then transferred onto a photomask or screen.

- Substrate Preparation: The material to be etched is cleaned and prepared to ensure optimal adhesion of the resist.

- Resist Application: A protective coating, known as a resist, is applied to the substrate. This resist will protect the areas of the material that are not to be etched.

- Pattern Transfer: The design from the photomask or screen is transferred onto the resist using UV light or other methods.

- Etching: The substrate is immersed in or sprayed with a chemical etchant solution. This solution selectively removes the material from the unprotected areas, leaving behind the desired pattern.

- Resist Removal and Cleaning: The remaining resist is removed, and the etched part is cleaned to remove any residual chemicals.

- Finishing (Optional): Depending on the application, additional finishing processes like plating, polishing, or coating may be applied.

Why Choose Chemical Etching Services?

- High Precision and Accuracy: Chemical etching can achieve extremely fine details and tight tolerances that are often impossible with other methods.

- Cost-Effectiveness for Complex Designs: For intricate parts, chemical etching can be more cost-effective than machining, especially in high-volume production.

- Versatility: It can be used on a wide range of metals, including stainless steel, aluminum, copper, and titanium, as well as some non-metallic materials.

- Stress-Free Manufacturing: Unlike mechanical processes, chemical etching does not introduce stress into the material, preserving its integrity.

- Rapid Prototyping and Production: Chemical etching can be used for both rapid prototyping and high-volume production runs.

- Design Flexibility: Allows for complex and intricate designs that may be difficult or impossible to achieve with other methods.

Applications of Chemical Etching Services:

- Electronics: Manufacturing lead frames, connectors, and other precision components.

- Aerospace: Creating lightweight and complex parts for aircraft and spacecraft.

- Automotive: Producing precision components for engines and other systems.

- Medical Devices: Fabricating implants, surgical tools, and diagnostic equipment.

- Decorative and Artistic Applications: Creating intricate designs on metal surfaces for jewelry, signage, and art pieces.

- Filters and Grids: Manufacturing precision filters and grids for various industrial applications.

Choosing the Right Chemical Etching Service Provider:

When selecting a chemical etching service provider, consider the following:

- Experience and Expertise: Look for a company with a proven track record and experience in handling your specific material and design requirements.

- Quality Control: Ensure the provider has robust quality control processes in place to guarantee consistent and accurate results.

- Equipment and Technology: Choose a provider with state-of-the-art equipment and technology to ensure high precision and efficiency.

- Customer Service and Communication: Select a provider that offers excellent customer service and communication throughout the project.

- Turnaround Time: Consider the provider’s turnaround time to ensure they can meet your deadlines.

In conclusion, chemical etching services offer a powerful and versatile solution for creating precise and intricate parts. By understanding the process and choosing the right provider, you can leverage this technology to achieve exceptional results for your specific application.