Etching for Metal Metal etching, a process that might sound intimidating, is actually a fascinating and versatile technique used to create intricate designs, markings, and even structural components on metal surfaces. It involves using chemicals or other etching agents to selectively remove material from a metal substrate, leaving behind a desired pattern or form.1

Understanding the Basics:

Etching for Metal At its core, metal etching relies on the principle of controlled corrosion. A protective layer, called a resist, is applied to the metal surface, covering the areas that are not intended to be etched. The resist can be applied in various ways, including using specialized inks, tapes, or even photoresist techniques. Once the resist is in place, the metal is immersed in or exposed to an etchant, a chemical solution that reacts with the exposed metal, dissolving it away.2

Why Etch Metal?

The applications of metal etching are vast and span across numerous industries:

- Art and Jewelry: Etching for Metal Creating intricate designs, textures, and patterns on metal pieces.3

- Electronics: Etching for Metal Manufacturing printed circuit boards (PCBs) by selectively removing copper from a laminate.4

- Industrial Applications: Etching for Metal Producing precise metal parts, nameplates, stencils, and signage.5

- Aerospace and Automotive: Etching for Metal Creating lightweight and complex components with tight tolerances.6

- Medical Devices: Etching for Metal Fabricating intricate implants and surgical tools.7

Types of Etching:

There are two main categories of metal etching:

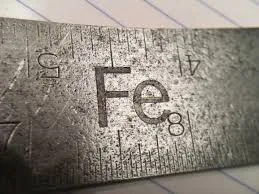

- Chemical Etching: This is the most common method, utilizing acids or other corrosive solutions to dissolve the metal. The specific etchant used depends on the type of metal being etched. For example, ferric chloride is often used for copper, while nitric acid is used for stainless steel.

- Electrochemical Etching: This method uses an electrolytic solution and an electric current to remove metal.8 It offers greater control over the etching process and can be used for more complex shapes and materials.9

The Etching Process in Detail:

- Preparation: The metal surface is cleaned and prepared to ensure proper adhesion of the resist.10

- Resist Application: The resist is applied to the metal surface, covering the areas that will remain after etching.

- Patterning: The desired pattern is transferred onto the resist, either manually or using photographic techniques.11

- Etching: The metal is immersed in or exposed to the etchant, which selectively removes the exposed metal.12

- Resist Removal: After the desired depth of etching is achieved, the resist is removed, leaving behind the final pattern.

- Cleaning and Finishing: The etched metal is cleaned and may undergo further finishing processes, such as polishing or coating.13

Factors Affecting Etching:

Several factors influence the etching process and the final result:

- Etchant Concentration and Temperature: Higher concentrations and temperatures generally result in faster etching rates.14

- Etching Time: The longer the metal is exposed to the etchant, the deeper the etch will be.15

- Metal Type: Different metals react differently to etchants, requiring specific solutions and parameters.16

- Resist Type: The choice of resist depends on the etchant used and the desired level of detail.

Safety Precautions:

Metal etching involves working with potentially hazardous chemicals.17 It’s crucial to follow safety guidelines and wear appropriate personal protective equipment, including gloves, eye protection, and respiratory protection.

In Conclusion:

Metal etching is a powerful and versatile technique that enables the creation of intricate designs and precise components on metal surfaces.18 By understanding the principles and processes involved, you can unlock the potential of this fascinating method for a wide range of applications. Whether you’re an artist, engineer, or hobbyist, metal etching offers a unique way to bring your ideas to life.