Chemical Etching is a versatile and widely used process for shaping and modifying materials by selectively removing parts of them using chemical reactions.1 It’s essentially a controlled corrosion technique, where a chemical solution, known as an etchant, is used to dissolve specific areas of a material while leaving others untouched.2 This process allows for intricate patterns, precise dimensions, and smooth surface finishes, making it indispensable in various industries.3

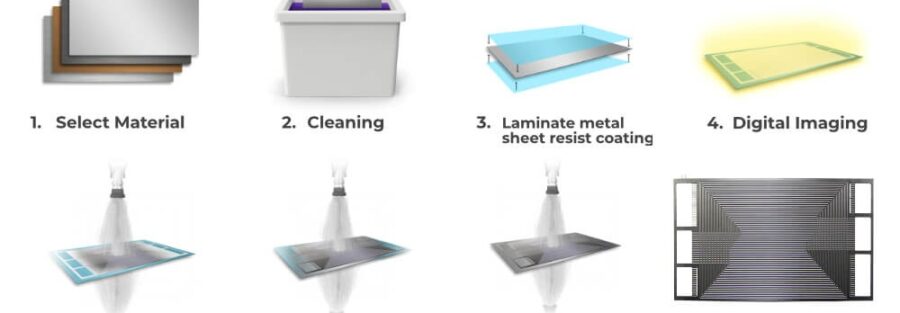

The Basic Process:

The fundamental principle behind chemical etching involves:

- Masking: A protective layer, called a mask or resist, is applied to the material’s surface.4 This mask is designed to be resistant to the etchant and is patterned to define the areas that will not be etched.5

- Etching: The material is immersed in or sprayed with the etchant solution.6 The etchant reacts with the unmasked areas, dissolving them at a controlled rate.7

- Resist Removal: After the desired amount of material is removed, the resist is stripped away, leaving behind the patterned design on the material’s surface.

| Feature | Description | Advantages | Disadvantages/Challenges | Applications |

| Process Overview | Controlled removal of material using chemical reactions. Involves masking, etching, and resist removal. | High precision, versatility, cost-effectiveness (for both small & large scale), smooth surface finish, stress-free processing. | Etchant selection is crucial, potential environmental impact, undercutting, achieving uniform etching. | Electronics (PCBs, ICs, MEMS), aerospace, automotive, jewelry & arts, medical devices, signage. |

| Masking | Application of a protective layer (resist) to define areas to be etched. | Allows for intricate patterns and precise dimensions. | Requires careful selection of resist material compatible with the etchant. | All applications requiring patterned etching. |

| Etching (Wet) | Immersion in a liquid etchant. | Simple, cost-effective, suitable for large-scale production. | Potential for undercutting, less precise than dry etching. | General industrial applications. |

| Etching (Dry) | Uses gases or plasmas as etchants. | Higher precision, anisotropic etching (directional). | More complex and expensive than wet etching. | Microfabrication, semiconductor manufacturing. |

| Etchant | Chemical solution used to dissolve material. | Determines the etching rate and selectivity. | Requires careful selection based on material and desired outcome. Can be hazardous. | Varies depending on material being etched (e.g., acids, bases, solvents). |

| Resist Removal | Stripping the protective layer after etching. | Leaves behind the patterned design on the material’s surface. | Requires appropriate solvents or techniques. | Essential step in all etching processes. |

| Precision & Control | Ability to create intricate and detailed patterns with tight tolerances. | Key advantage for applications requiring high accuracy. | Undercutting and uniformity can be challenges. | Critical in electronics, medical devices, and aerospace. |

| Materials | Applicable to a wide range of materials. | Versatility across various industries. | Etchant compatibility is essential. | Metals, glass, ceramics, polymers. |

| Environmental Impact | Potential for hazardous waste generation. | Requires careful handling and disposal of etchants. | Regulations and sustainable practices are important. | All applications involving chemical etching. |

Types of Etching:

Chemical etching can be broadly classified into two main categories:

- Wet Etching: This is the most common type, where the material is immersed in a liquid etchant. It’s relatively simple and cost-effective, suitable for large-scale production.8

- Dry Etching: This method uses gases or plasmas as etchants.9 It offers higher precision and anisotropy (directional etching), making it ideal for microfabrication and semiconductor manufacturing.10

Applications Across Industries:

Chemical etching finds applications in a wide range of industries:

- Electronics: Manufacturing printed circuit boards (PCBs), integrated circuits (ICs), and microelectromechanical systems (MEMS).11

- Aerospace: Creating lightweight and complex components for aircraft and spacecraft.12

- Automotive: Producing intricate parts for engines, dashboards, and other components.13

- Jewelry and Arts: Designing detailed patterns and engravings on metals.

- Medical Devices: Fabricating precision components for implants and surgical instruments.14

- Signage and Decorative Items: Creating custom designs on various materials.15

Advantages of Chemical Etching:

- High Precision: Enables the creation of intricate and detailed patterns with tight tolerances.16

- Versatility: Can be used on a wide range of materials, including metals, glass, ceramics, and polymers.

- Cost-Effectiveness: Suitable for both small and large-scale production.17

- Smooth Surface Finish: Achieves a uniform and smooth surface after etching.18

- Stress-Free Processing: Unlike mechanical machining, chemical etching doesn’t induce stress in the material.19

Considerations and Challenges:

- Etchant Selection: Choosing the right etchant for the specific material is crucial for achieving desired results.20

- Environmental Impact: Some etchants can be hazardous and require careful handling and disposal.21

- Undercutting: The etchant can sometimes dissolve material under the resist, leading to unwanted features.22

- Uniformity: Achieving uniform etching across the entire surface can be challenging, especially for large areas.

Conclusion:

Chemical etching is a powerful and versatile technique that offers a unique way to shape and modify materials with high precision.23 Its ability to create intricate designs and smooth surfaces makes it an indispensable tool in numerous industries. As technology advances, chemical etching continues to evolve, finding new applications and contributing to the development of innovative products.24