Chemical Etching Process , a subtractive manufacturing process, involves using chemicals to remove material from a substrate, creating intricate designs and patterns. It’s a technique that blends precision with versatility, finding applications in everything from microelectronics to artistic metalwork. Let’s delve into the intricacies of this fascinating process.

The Basic Principle:

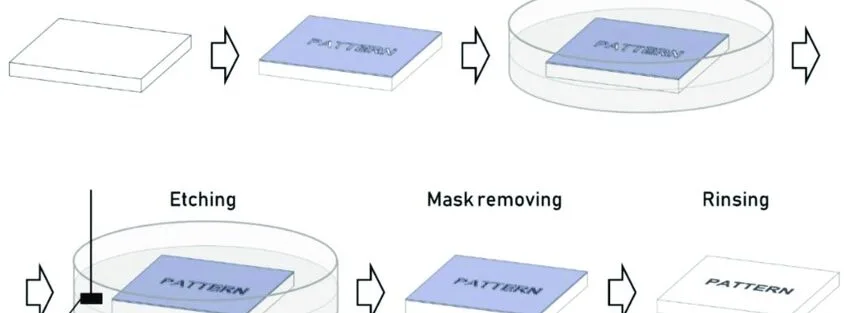

At its core, chemical etching relies on the selective removal of material using chemical reactants, known as etchants. This selectivity is achieved by protecting certain areas of the substrate with a mask or resist, while exposing the unprotected areas to the etchant. The etchant then reacts with the exposed material, dissolving it and leaving behind the desired pattern.

| Category | Description/Details | Key Aspects | Applications |

| Basic Principle | Selective removal of material using chemical reactants (etchants) by protecting certain areas with a mask/resist. | * Substrate + Etchant = Patterned Substrate <br> * Masking/Resist for selective removal. | Microelectronics, aerospace, automotive, medical devices, art/jewelry, printing. |

| Process Steps | 1. Substrate Preparation <br> 2. Masking/Resist Application <br> 3. Patterning the Resist <br> 4. Etching (chemical reaction) <br> 5. Resist Removal <br> 6. Cleaning & Finishing | * Substrate cleaning, resist application, pattern creation (photolithography, screen printing, laser ablation), etching with etchant, resist removal, final cleaning/finishing. | |

| Types of Etchants | Acids (hydrochloric, nitric, sulfuric), Alkalis (sodium hydroxide, potassium hydroxide), Salts (ferric chloride, ammonium persulfate). | * Choice depends on substrate material. <br> * Acids for metals, alkalis for silicon, salts for copper. | |

| Types of Etching Processes | Wet Etching (immersion in etchant), Dry Etching (plasma/vapor of etchant gases). | * Wet: Simple, cost-effective, less precise. <br> * Dry: High precision, anisotropy, complex, expensive. | |

| Advantages | High precision, versatility (wide range of materials), cost-effectiveness (high volume), scalability. | * Intricate patterns with tight tolerances. <br> * Applicable to various materials and scales. | |

| Challenges | Environmental concerns (hazardous etchants), undercutting (inaccuracies), etch rate control. | * Requires careful handling and disposal of chemicals. <br> * Potential for material removal under resist. <br> * Maintaining consistent etch rate. | |

| Future Trends | Development of environmentally friendly etchants, increased precision, advancements in dry etching techniques. | * Focus on sustainable and precise processes. |

The Process Explained:

- Substrate Preparation: The process begins with cleaning the substrate, ensuring it’s free from contaminants that could interfere with the etching process.

- Masking/Resist Application: A protective layer, called a resist, is applied to the substrate. This resist can be a photopolymer, a screen-printed ink, or even a wax-based material. The method of application depends on the desired pattern and the substrate material.

- Patterning the Resist: The resist is then patterned to create the desired design. This can be achieved through photolithography (using UV light and a photomask), screen printing, or laser ablation.

- Etching: The substrate is immersed in or sprayed with an etchant solution. The etchant reacts with the exposed areas of the substrate, removing material at a controlled rate.

- Resist Removal: After the etching process is complete, the resist is removed, leaving behind the desired pattern on the substrate.

- Cleaning and Finishing: The etched substrate is cleaned to remove any residual etchant and undergo further finishing processes, such as polishing or coating, if required.

The choice of etchant depends on the substrate material. Common etchants include:

- Acids: Hydrochloric acid, nitric acid, sulfuric acid, and mixtures like aqua regia are used for etching metals.

- Alkalis: Sodium hydroxide and potassium hydroxide are used for etching silicon and other materials.

- Salts: Ferric chloride and ammonium persulfate are used for etching copper and other metals.

Types of Etching Processes:

- Chemical Etching Process Wet Etching: The substrate is immersed in an etchant solution. This is a simple and cost-effective method, but it can be less precise than dry etching.

- Chemical Etching Process Dry Etching: The substrate is exposed to a plasma or vapor of etchant gases. This method offers higher precision and anisotropy (directional etching) but is more complex and expensive.

Applications of Chemical Etching:

- Chemical Etching Process Microelectronics: Creating intricate circuits and components on silicon wafers.

- Chemical Etching Process Aerospace: Manufacturing lightweight and complex parts for aircraft and spacecraft.

- Chemical Etching Process Automotive: Producing precision components for engines and other systems.

- Chemical Etching Process Medical Devices: Fabricating implants and surgical tools.

- Chemical Etching Process Art and Jewelry: Creating detailed designs on metal surfaces.

- Chemical Etching Process Printing: Manufacturing printing plates and dies.

Advantages of Chemical Etching:

- High Precision: Capable of creating intricate patterns with tight tolerances.

- Versatility: Can be used on a wide range of materials.

- Cost-Effectiveness: Especially for high-volume production.

- Scalability: Can be used to create both small and large parts.

Challenges of Chemical Etching:

- Environmental Concerns: Some etchants can be hazardous and require careful handling and disposal.

- Undercutting: The etchant can sometimes remove material under the resist, leading to inaccuracies.

- Etch Rate Control: Maintaining a consistent etch rate can be challenging.

The Future of Chemical Etching:

As technology advances, chemical etching continues to evolve. Researchers are developing new etchants and processes that are more environmentally friendly and offer even greater precision. The future of chemical etching holds exciting possibilities for creating even more intricate and functional devices.

In conclusion, chemical etching is a powerful manufacturing process that enables the creation of complex and precise designs on a wide range of materials. Its versatility, cost-effectiveness, and scalability make it an indispensable tool in various industries. As technology continues to advance, chemical etching will likely play an even more significant role in shaping the future of manufacturing.