five-Axis Machining has revolutionized manufacturing, permitting the advent of complex geometries with unprecedented precision. While it would sound intimidating, the idea is quite straightforward. Let’s damage down what five-axis machining is, how it works, and why it is so precious.

5-Axis Machining: Key Information

| Feature | Description | Benefits | Applications | Considerations | ||

| Definition | Machining process using five axes (X, Y, Z linear; A, B/C rotational) for simultaneous movement. | Increased design freedom, reduced setups, improved surface finish, shorter cycle times, enhanced precision. | Aerospace, medical, automotive, tool & die, energy. | Higher initial cost, requires skilled operators, advanced programming needed. | ||

| Axes | * X-axis: Horizontal linear movement. <br> * Y-axis: Depth linear movement. <br> * Z-axis: Vertical linear movement. <br> * A-axis: Rotation around X-axis (tilting). <br> * B/C-axis: Rotation around Y/Z-axis (rotation). | Enables complex geometry machining from multiple angles. | All applications listed can benefit from complex geometry. | Proper axis configuration selection is crucial. | ||

| Working Principle | Coordinated movement of all five axes to position the cutting tool or workpiece. | Optimal cutting angles, fewer setups, efficient tool paths. | Complex parts requiring high accuracy. | Requires precise synchronization of axis movements. | ||

| Machine Types | * Trunnion-style: Workpiece on a tilting/rotating table. <br> * Swivel-head style: Cutting tool head tilts/rotates. <br> * Hybrid: Combines both designs. | Versatility for various part sizes and complexities. | Selection depends on application requirements. | Machine selection impacts achievable geometries. | ||

| Advantages | * Complex shape machining. <br> * Reduced setups. <br> * Improved surface finish. <br> * Shorter cycle times. <br> * Enhanced precision. <br> * Increased design freedom. <br> * Better tool life. | Increased productivity, higher part quality, reduced costs. | Industries needing high-value, complex parts. | Requires careful planning and programming to maximize benefits. | ||

| Disadvantages | * Higher initial investment. <br> * Requires skilled operators. <br> * Complex programming. <br> * More complex maintenance. | Potential cost barrier, skill gap. | Less suitable for simple, high-volume parts. | Thorough training and maintenance are essential. | ||

| Surface Finish | Achieves a superior surface finish. | Reduced post processing. | All applications where surface finish is important. | Requires good tool selection, and proper programming. | ||

| Tool Life | Optimal cutting angles allow for longer tool life. | Reduces tooling costs. | All applications. | Proper speeds and feeds are required. |

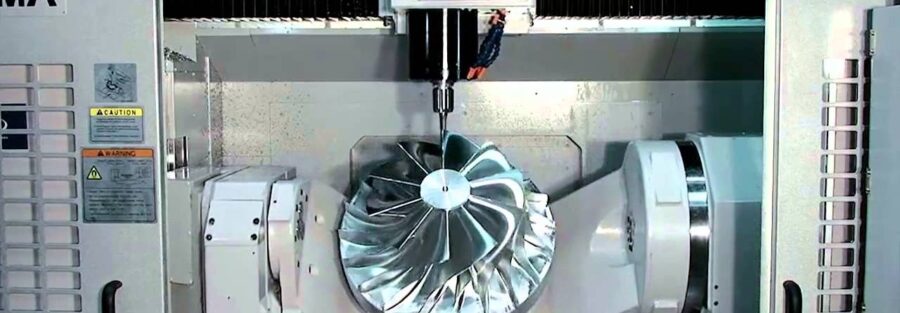

What is 5-Axis Machining?

Traditional machining normally entails 3 linear axes: X, Y, and Z. These axes manage the motion of the cutting tool alongside a three-dimensional aircraft. Five-axis machining takes this a step in addition by using adding rotational axes, permitting the reducing tool or the workpiece to rotate around additional axes.

Imagine a widespread milling device. It can circulate the device left/proper (X), forward/backward (Y), and up/down (Z). Now, photo adding a desk that can tilt and rotate. This tilting and rotation are the 2 extra axes that define five-axis machining.

The Five Axes Explained:

- X-axis: Linear movement along the horizontal aircraft.

- Y-axis: Linear motion along the intensity plane.

- Z-axis: Linear movement along the vertical plane.

- A-axis: Rotational motion across the X-axis (tilting).

- B-axis (or C-axis): Rotational movement across the Y-axis (or Z-axis, depending at the system configuration).

These five axes can work concurrently, permitting the cutting device to method the workpiece from surely any attitude.

How five-Axis Machining Works:

The center principle entails the coordinated motion of all 5 axes. This lets in for:

- Complex Shapes: Machining elaborate geometries with undercuts, curved surfaces, and complicated angles turns into viable in a unmarried setup.

- Reduced Setups: Traditionally, machining such elements might require multiple setups, every with its personal fi