Laser Engraving Metal: Have you ever seen intricate designs or personalized messages etched onto metal objects? This is likely the work of laser engraving, a technology that allows for precise and permanent markings on various metal surfaces.

| Feature | Description |

| Definition | A process that uses a high-powered laser beam to remove a thin layer of material from the metal surface, creating a permanent mark or design. |

| Process | 1. Design Creation: The image or text is created digitally. <br> 2. Laser Focus: A laser beam is focused on the metal. <br> 3. Material Removal: The laser vaporizes or melts metal. <br> 4. Cooling: The metal is cooled. <br> 5. Finishing: The engraved area may be cleaned or polished. |

| Applications | – Industrial manufacturing <br> – Medical field <br> – Art and crafts <br> – Awards and trophies |

| Benefits | – Precision and accuracy <br> – Durability <br> – Versatility <br> – Customization |

What is Laser Engraving Metal?

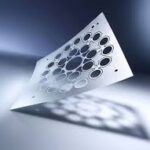

Laser engraving is a process that uses a high-powered laser beam to remove a thin layer of material from the metal surface, creating a permanent mark or design. The laser is guided by a computer-generated image, ensuring accuracy and consistency.

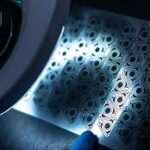

How Does Laser Engraving Metal Work?

- Design Creation: Laser Engraving Metal:The desired image or text is created digitally.

- Laser Focus: A powerful laser beam is focused on the specific areas of the metal to be engraved.

- Material Removal: The intense heat from the laser vaporizes or melts the targeted metal, creating the desired mark or design.

- Cooling: The metal is cooled to prevent warping or damage.

- Finishing: The engraved area may be cleaned or polished to enhance the finished look.

Applications of Laser Engraving Metal

Laser engraving metal has a wide range of applications across various industries:

- Industrial Manufacturing:

- Marking tools and equipment with serial numbers and identification codes

- Creating custom-made nameplates and labels

- Engraving precision parts for machinery and electronics

- Medical Field:

- Marking surgical instruments and implants

- Creating personalized medical devices

- Art and Crafts:

- Creating unique jewelry and decorative pieces

- Personalizing metal sculptures and artworks

- Awards and Trophies:

- Engraving personalized awards and trophies

Benefits of Laser Engraving Metal

- Precision and Accuracy: Laser engraving allows for highly precise and accurate markings with intricate details.

- Durability: Engraved markings are permanent and resistant to wear and tear.

- Versatility: Laser engraving can be used on a wide range of metals, including stainless steel, aluminum, brass, and copper.

- Customization: Laser engraving allows for complete customization, enabling the creation of unique and personalized items.

In Conclusion

Laser engraving is a versatile and efficient technology that offers numerous benefits for marking and customizing metal objects. From industrial applications to personalized gifts, laser engraving adds a touch of precision and personality to various metal surfaces.