A laser marking machine is a cutting-edge piece of technology that uses concentrated beams of light to engrave or mark surfaces with high precision. It is widely used in industries such as manufacturing, automotive, electronics, jewelry, and healthcare, offering unmatched accuracy and durability for marking various materials, including metals, plastics, ceramics, and glass.

How Laser Marking Machines Work

Laser marking machines operate by directing a laser beam onto a surface, creating a permanent mark without physical contact. The process works by altering the material’s properties or appearance through:

Engraving: The laser beam removes material to create a deep mark.

Annealing: Heat changes the material’s color, typically used for metals.

Foaming: Generates bubbles in the material to create a raised, lighter mark.

Coloration: Alters the material’s color for visual contrast.

Carbon Migration: Brings carbon to the surface for darker marks, often used on metals.

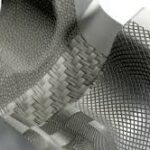

Types of Laser Marking Machines

Fiber Laser Marking Machine:

Best suited for marking metals and hard plastics.

High efficiency and low maintenance.

Commonly used in electronics, automotive, and aerospace industries.

CO2 Laser Marking Machine:

Ideal for marking non-metal materials like wood, paper, leather, and acrylic.

Frequently used in packaging, textiles, and crafting industries.

UV Laser Marking Machine:

Specializes in precision marking on sensitive materials like glass and ceramics.

Used in industries requiring fine details, such as electronics and medical equipment.

Green Laser Marking Machine:

Designed for reflective surfaces like glass and certain metals.

Ensures high contrast and readability.

Advantages of Laser Marking Machines

High Precision: Laser marking achieves sharp, clear, and permanent marks, making it suitable for intricate designs and small text.

Non-Contact Process: The laser beam does not physically touch the material, ensuring minimal wear and tear.

Versatility: Capable of marking various materials with different shapes and sizes.

Eco-Friendly: No harmful chemicals are involved, and it produces minimal waste.

Durability: Laser marks are resistant to fading, corrosion, and wear, ensuring long-lasting quality.

Automation-Friendly: Easily integrates with automated production lines, enhancing efficiency and productivity.

Applications of Laser Marking Machines

Electronics and Semiconductors: Marking circuit boards, chips, and components with barcodes, serial numbers, and logos.

Automotive: Engraving VIN numbers, logos, and other identification marks on parts.

Jewelry: Creating intricate designs, patterns, and personalizations on precious metals.

Medical Devices: Marking instruments, implants, and packaging with serial numbers and regulatory information.

Packaging: Adding barcodes, QR codes, and expiry dates on labels and containers.

Textiles and Apparel: Engraving leather and fabric for branding and customization.

Key Considerations When Choosing a Laser Marking Machine

Material Compatibility: Ensure the machine can handle the materials you work with.

Marking Speed and Precision: Choose a machine that balances speed with the level of detail required.

Power and Wavelength: Select a machine with appropriate power and wavelength for your applications.

Software Features: Look for user-friendly software that offers customization and integration options.

Maintenance and Support: Opt for machines with low maintenance requirements and reliable customer support.

Future Trends in Laser Marking

The laser marking industry is evolving rapidly with advancements in technology. Emerging trends include:

Enhanced Automation: Integration with AI and IoT for smarter production lines.

Green Technology: Development of energy-efficient and eco-friendly laser systems.

Miniaturization: Compact machines for small-scale operations and portable applications.

Increased Versatility: Machines capable of handling more materials and complex tasks.

Conclusion

A laser marking machine is an invaluable tool for industries requiring precision, efficiency, and durability in their marking processes. With a wide range of applications and types, these machines cater to diverse needs, making them a cornerstone of modern manufacturing and production. Investing in the right laser marking machine can significantly enhance product quality, traceability, and brand identity.