Laser Marking Machines for Metal have become indispensable tools for permanently marking metal components across a vast spectrum of industries. From serial numbers on critical aircraft parts to decorative engravings on jewelry, these machines offer unparalleled precision, speed, and durability. This article delves into the specifics of laser marking on metal, exploring the technologies, applications, and advantages that make it a superior marking solution.

Laser Marking on Metal

| Feature | Description | Benefits | Applications |

| Process | Uses a focused laser beam to alter the surface of metal. | Non-contact, precise, permanent, versatile. | Marking, engraving, branding, serialization. |

| Laser Type (Preferred) | Fiber Laser | High beam quality, power density, and speed. | Marking various metals (steel, aluminum, titanium, etc.). |

| Marking Mechanisms | Vaporization, melting, annealing | Creates different visual and tactile effects. | Vaporization: Deep engravings. Melting: Raised marks. Annealing: Color change. |

| Metals | Wide range, including steel, aluminum, stainless steel, titanium, brass, copper, and more. | Adaptable to diverse metal types. | Industrial parts, tools, jewelry, medical devices. |

| Advantages | Precision, speed, permanence, non-contact, digital control, automation | Superior to traditional metal marking methods. | High-quality, efficient, durable markings. |

| Industries Served | Aerospace, automotive, medical devices, electronics, tooling, jewelry, manufacturing, and more. | Wide applicability across sectors using metal components. | Part marking, product identification, branding, customization. |

| Key Applications | Part marking, serial numbers, barcodes, QR codes, logos, engravings, UDI marking, tool marking. | Essential for traceability, branding, and customization of metal products. | Manufacturing, logistics, retail, healthcare. |

| Comparison with CO2 Laser | Fiber lasers are generally preferred for metal due to higher power density and precision. | More efficient and versatile for metal marking. | While CO2 can mark some metals, fiber is the typical choice. |

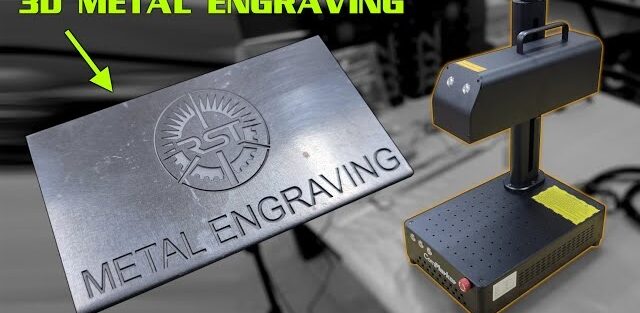

| Future Trends | Enhanced 3D marking, integration with smart manufacturing, increased speed and precision. | Continuous improvement and innovation in metal marking technology. | More efficient, versatile, and automated metal marking solutions. |

The Science Behind the Mark: How Lasers Interact with Metal

Laser Marking Machines for Metal typically involves using a focused beam of light to alter the metal’s surface. Unlike traditional methods like mechanical engraving, laser marking is a non-contact process, eliminating the risk of tool wear and damage to the workpiece. When the laser beam interacts with the metal, several processes can occur:

- Vaporization: The intense heat of the laser can vaporize a thin layer of metal, creating a depression or mark. This is ideal for deep engravings and creating high-contrast markings.

- Melting: The laser’s energy can melt the surface layer of the metal, causing it to flow and create a raised or textured mark. This technique can be used for creating 3D-like effects.

- Annealing: In some cases, the laser’s heat can alter the metal’s crystalline structure without melting it. This results in a color change on the surface, often used for creating subtle but permanent markings.

Choosing the Right Laser: Fiber vs. CO2

Laser Marking Machines for Metal While CO2 lasers can mark some metals, fiber lasers are generally preferred for metal marking due to their superior beam quality and power density. Fiber lasers offer several advantages:

- High Precision: Fiber lasers produce a very small and highly focused beam, enabling extremely fine and detailed markings.

- High Speed: Fiber lasers can mark metals at high speeds, making them ideal for high-volume production.

- Durability: Fiber laser systems are robust and require minimal maintenance.

- Versatility: Fiber lasers can mark a wide range of metals, including steel, aluminum, stainless steel, titanium, brass, and more.

Applications Across Industries: From Aerospace to Jewelry

Laser Marking Machines for Metal The versatility of laser marking on metal has led to its widespread adoption across diverse industries:

- Aerospace: Marking critical components with part numbers, serial numbers, and barcodes for traceability and identification.

- Automotive: Marking engine parts, chassis numbers, and other components for quality control and anti-counterfeiting measures.

- Medical Devices: Sterile marking of surgical instruments, implants, and medical equipment with unique device identifiers (UDIs).

- Electronics:Laser Marking Machines for Metal electronic components, circuit boards, and connectors with logos, serial numbers, and other information.

- Tooling: Laser Marking Machines for Metal and dies with identification numbers, sizes, and other relevant information.

- Jewelry: Engraving personalized messages, intricate designs, and hallmarks on rings, necklaces, and other jewelry items.

- Manufacturing: General part marking, branding, and serialization across various manufacturing sectors.

Advantages of Laser Marking on Metal: A Superior Solution

Compared to traditional marking methods, laser marking offers several distinct advantages:

- Permanent Mark: Laser marks on metal are highly durable and resistant to abrasion, chemicals, and extreme temperatures.

- High Precision: Laser marking can create extremely fine and detailed marks, allowing for complex designs and intricate patterns.

- High Speed: Laser marking is a fast process, making it suitable for high-volume production.

- Non-Contact: Laser marking doesn’t involve physical contact, eliminating the risk of damage to the workpiece.

- Digital Control: Laser marking is controlled by computer software, allowing for easy customization and automation.

The Future of Metal Marking: Advancements on the Horizon

The field of laser marking is constantly evolving, with ongoing research and development focused on improving speed, precision, and material compatibility. We can expect to see even more innovative applications of laser marking technology in the future, as it continues to push the boundaries of what’s possible in metal marking. From enhanced 3D marking capabilities to integration with smart manufacturing systems, laser marking is poised to play an even greater role in the future of metal fabrication and product identification.