Laser Mould Texturing:

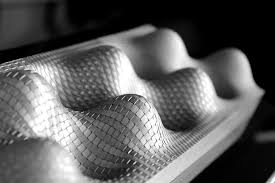

Precision and Versatility in Surface Engineering is a complicated production system that makes use of excessive-strength laser beams to create elaborate and specific textures on molds utilized in diverse manufacturing approaches. This technique is going beyond conventional mildew texturing strategies, providing advanced manage and versatility in reaching preferred surface finishes.

Laser Mold Texturing: An Overview

| Feature | Description |

| Function | Uses high-energy laser beams to create precise and intricate textures on molds. |

| Methods | Ablation, melting and reflow, inducing phase changes. |

| Benefits | Precision and control, versatility, non-contact, high throughput, reduced tooling costs. |

| Applications | Automotive, consumer goods, medical devices, packaging. |

| Impact | Enables the creation of products with enhanced aesthetics and functionality. |

| Future Trends | Multi-material processing, in-situ control, new applications. |

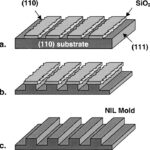

How Laser Mold Texturing Works:

Laser mould texturing entails directing a centered laser beam onto the mold floor. The laser’s strength may be used to:

Ablate: Remove cloth in a unique and controlled manner, developing microscopic functions like pits, grooves, or channels.

Melt and Reflow: Melt the surface layer, inflicting it to glide and shape textures.

Induce Phase Changes: Alter the cloth’s microstructure, developing regions with specific properties.

Advantages of Laser Mold Texturing:

Precision and Control: Laser texturing gives wonderful precision and control over the created textures, allowing for complex and difficult designs.

Versatility: Applicable to a extensive variety of mildew substances, such as metals, plastics, and ceramics.

Non-Contact Process: Reduces the danger of destructive the mold during processing.

High Throughput: Automation competencies enable high-extent production.

Reduced Tooling Costs: Laser texturing can remove the want for expensive and time-consuming conventional tooling methods.

Applications of Laser Mold Texturing:

Laser mold texturing reveals packages in various industries, consisting of:

Automotive: Creating textured dashboards, door panels, and steering wheels.

Consumer Goods: Texturing gadgets like kitchenware, electronics, and toys.

Medical Devices: Creating textured surfaces on implants and prosthetics for stepped forward biocompatibility.