Laser Texturing: A Precise and Versatile Surface Treatment

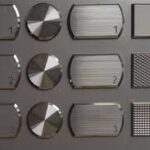

Laser texturing is a modern manufacturing system that uses high-electricity laser beams to create intricate patterns and textures on diverse substances. This approach offers a excessive degree of precision and manipulate, making an allowance for the introduction of complicated floor changes that could drastically beautify a cloth’s residences and performance.

Laser Texturing: An Overview

| Feature | Description |

| Process | Uses high-energy laser beams to create patterns and textures on material surfaces. |

| Methods | Ablation (material removal), melting and reflow, inducing phase changes. |

| Applications | Manufacturing, electronics, biomedical, and more. |

| Benefits | High precision, versatility, non-contact, high throughput. |

| Future Trends | Multi-material processing, in-situ control, new applications. |

| Examples | Creating non-stick surfaces, improving wear resistance, enhancing heat dissipation. |

How Does Work?

involves directing a centered laser beam onto the material’s surface. The laser’s energy can be used to:

Ablate: Remove material in a particular way, growing microscopic functions like pits, grooves, or channels.

Melt and Reflow: Melt the surface layer, inflicting it to glide and shape textures.

Induce Phase Changes: Alter the fabric’s microstructure, growing areas with one-of-a-kind homes.

Applications

has a wide variety of applications across numerous industries, which include:

Manufacturing:

Creating non-stick surfaces on cookware and molds.

Improving the wear resistance and fatigue existence of mechanical additives.

Enhancing the adhesion of coatings and adhesives.

Electronics:

Creating microfluidic channels for lab-on-a-chip gadgets.

Improving the performance of solar cells and LEDs.

Enhancing the heat dissipation of electronic additives.

Biomedical:

Creating biocompatible surfaces for implants and prosthetics.

Designing surfaces for tissue engineering and drug transport.

Improving the sensitivity of biosensors.

Advantages

Precision and Control: Laser texturing lets in for particular control over the shape,