Mold Etching Process

Mold Etching Process is a manufacturing manner that includes growing problematic textures on the floor of molds utilized in numerous manufacturing techniques, including injection molding, blow molding, and rotational molding. This system permits for the manufacturing of gadgets with precise and visually appealing surface finishes.

Mold Etching Process: An Overview

| Feature | Description |

| Function | Creates intricate textures on molds used in manufacturing processes. |

| Methods | Chemical etching, electrochemical etching. |

| Benefits | Enhanced aesthetics, improved functionality (slip resistance, anti-reflection, heat dissipation, increased surface area). |

| Applications | Automotive, consumer goods, medical devices, packaging. |

| Impact | Enables the production of products with unique and functional surface finishes. |

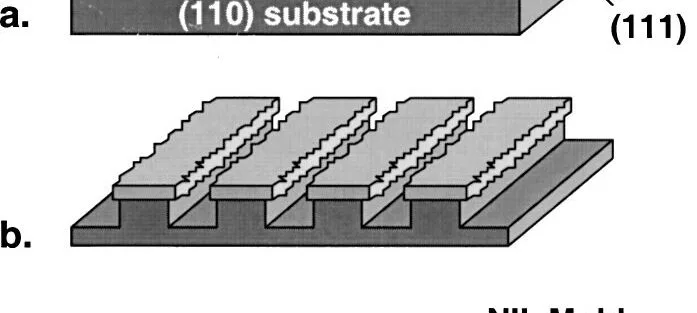

How Mold Etching Works:

Mold etching usually entails primary methods:

Chemical Etching: In this manner, the mold is uncovered to a chemical answer that selectively gets rid of material from precise areas, growing the preferred texture. The intensity and complexity of the texture may be controlled through adjusting the etching time and the attention of the chemical solution.

Electrochemical Etching:

This method utilizes an electrical modern-day to dispose of cloth from the mold surface. The procedure entails immersing the mold in an electrolyte answer and making use of an electrical cutting-edge among the mold and an electrode. This reasons the cloth at the mildew’s surface to dissolve, developing the preferred texture.

Benefits of Mold Etching:

Enhanced Aesthetics:

Mold etching lets in manufacturers to create visually appealing and specific floor finishes on products, making them extra appealing to purchasers.

Improved Functionality: Textured surfaces can decorate product overall performance in numerous methods:

Slip Resistance: Creating textured surfaces on non-slip gadgets like car mats, bathe floors, and grips.

Anti-Reflective Properties: Reducing glare and improving visibility on surfaces like lenses and displays.

Improved Heat Dissipation: Enhancing warmth switch in programs like electronics cooling.

Increased Surface Area: Creating textures on merchandise like filters or heat exchangers to improve their efficient