Photo Etching is a producing process used to create specific, intricate shapes and styles on numerous materials, in general metals. It entails using light to selectively remove material from a metallic floor, ensuing in problematic designs and components.

| Feature | Description |

| What it is | A manufacturing process that uses light to selectively remove material from a metal surface to create precise shapes and patterns. |

| How it works | 1. Photoresist application <br> 2. Photographic exposure <br> 3. Development <br> 4. Etching <br> 5. Stripping |

| Advantages | High precision, versatility, repeatability, cost-effectiveness, wide applications |

| Applications | Electronics, aerospace, medical devices, jewelry, decorative items |

| Key Benefits | Creates intricate details, works with various metals, consistent results, cost-effective for high volume |

How Does Work?

The system typically includes these steps:

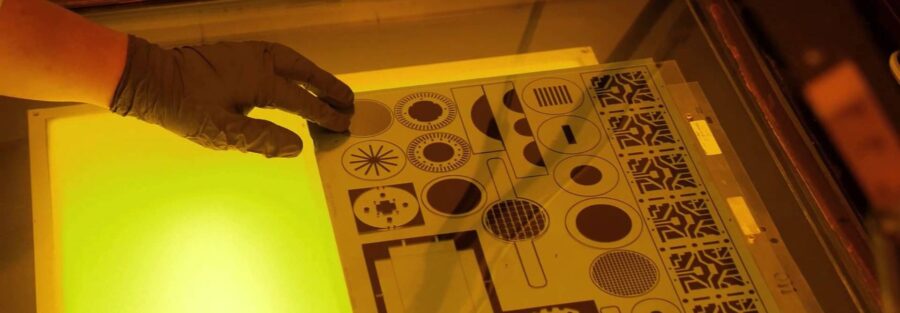

Photoresist Application: A mild-sensitive material called a photoresist is applied to the metallic floor.

Photographic Exposure: The photoresist-lined metal is uncovered to light through a masks or stencil. The masks blocks light in regions wherein the metallic is to be etched away.

Development: The uncovered photoresist is advanced, casting off the exposed areas and leaving at the back of a sample that acts as a shielding masks.

Etching: The steel is then immersed in an etching solution that removes the unprotected regions, creating the favored form or pattern.

Stripping: The final photoresist is stripped away, leaving behind the finished etched metal component.

What are the Advantages of Photo Etching?

Photo etching offers several advantages over conventional manufacturing techniques:

High Precision: It allows for the introduction of extraordinarily pleasant information and complex shapes with high accuracy.

Versatility: It may be used on numerous metals, which includes stainless-steel, aluminum, copper, and brass.

Repeatability: The process is tremendously repeatable, making sure steady consequences.

Cost-Effectiveness: It may be value-effective for excessive-volume production of difficult elements.

Wide Applications: It reveals applications in various industries, such as electronics, aerospace, scientific devices, and jewellery.

What are Photo Etching Used For?

Photo etching is used to create a wide range of additives and products, along with: