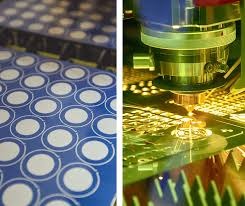

Photo Etching: Have you ever seen a beautiful image etched onto a piece of metal, like a custom-made nameplate or a detailed artwork? If so, you’ve likely encountered the work of photo etching.

| Feature | Description |

| Definition | A process used to create intricate designs and patterns on metal surfaces by using a light-sensitive material called a “photoresist”. |

| Process | 1. Image Preparation: The image is created digitally and converted into a film negative. <br> 2. Photoresist Application: A photoresist is applied to the metal. <br> 3. Image Exposure: The metal is exposed to light through the negative. <br> 4. Chemical Etching: Exposed areas are etched away. <br> 5. Photoresist Removal: The remaining photoresist is removed. |

| Applications | – Industrial manufacturing <br> – Medical field <br> – Art and crafts <br> – Awards and trophies |

| Benefits | – Precision and detail <br> – Durability <br> – Versatility <br> – Customization |

What is Photo Etching?

Photo etching is a process used to create intricate designs and patterns on metal surfaces. It involves using a light-sensitive material called a “photoresist” to transfer an image onto the metal.

How Does Photo Etching Work?

- Image Preparation: Photo Etching: The desired image is created digitally and converted into a film negative.

- Photoresist Application: Photo Etching A thin layer of photoresist is applied to the metal surface.

- Image Exposure: Photo Etching: The photoresist-coated metal is exposed to light through the film negative. The exposed areas of the photoresist harden, while the unexposed areas remain soft.

- Chemical Etching: Photo Etching:The metal is then placed in a chemical bath that etches away the exposed areas, leaving behind the desired image or pattern.

- Photoresist Removal: Finally, the remaining photoresist is removed, revealing the etched design.

Applications of Photo Etching

Photo Etching: has a wide range of applications across various industries:

- Industrial Manufacturing:

- Creating intricate circuit boards for electronics

- Manufacturing precision parts for machinery and aerospace

- Producing custom-made nameplates and identification tags

- Medical Field:

- Manufacturing surgical instruments and implants

- Creating intricate stents and other medical devices

- Art and Crafts:

- Creating unique jewelry and decorative pieces

- Producing custom-made artworks and sculptures

- Awards and Trophies:

- Engraving personalized awards and trophies

Benefits of Photo Etching

- Precision and Detail: Photo etching allows for the creation of highly detailed and intricate designs with exceptional precision.

- Durability: Etched images are durable and resistant to wear and tear.

- Versatility: Photo etching can be used on a wide range of metals, including stainless steel, brass, copper, and aluminum.

- Customization: Photo etching allows for complete customization, enabling the creation of unique and personalized items.

In Conclusion

Photo etching is a fascinating process that allows for the creation of beautiful and functional metal products. With its precision, durability, and versatility, photo etching continues to be a valuable technique in various industries.